1.Scope

The specifications should be applied to electret condenser microphone of DGO9745CD

2.Storage And Judgement Conditions

Temperature Range(°C) | Rel. Humidity(%) | Static Pressure(kPa) | |

Judgement | 19~21 | 60~70 | 86~106 |

Storage |

| ||

Operating | -20~60 |

3.Specifications

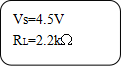

Test Conditions:VS=4.5V,RL=2.2KΩ,Temp=20±2°C, R.H=60±5%

ITEM | Symbol | Test Conditions | Min | Standard | Max | Unit | |||||

Sensitivity | S | f=1KHz, S.P.L=1μBar | -45 | -43 | -41 | dB 0dB=1V/Pa | |||||

Impedance | Z | f=1KHz, S.P.L=1μBar | 2.2 | KΩ | |||||||

Directivity | Omni-directional | ||||||||||

Current Consumption | I | 500 | μA | ||||||||

Operation Voltage Range | VS | 1.0 | 4.5 | 10 | V | ||||||

S/N Ratio | S/N(A) | f=1KHz,S.P.L=1Pa A Curve | 45 | dB | |||||||

Decreacing Voltage Characteristic | △S | f=1KHz,S.P.L=1Pa VS=4.5-3.0V | -3 | dB | |||||||

Max.Input Sound Level | MISPL | f=1KHz, Distortion≤3% | 115 | dB | |||||||

4.Frequency Response

|

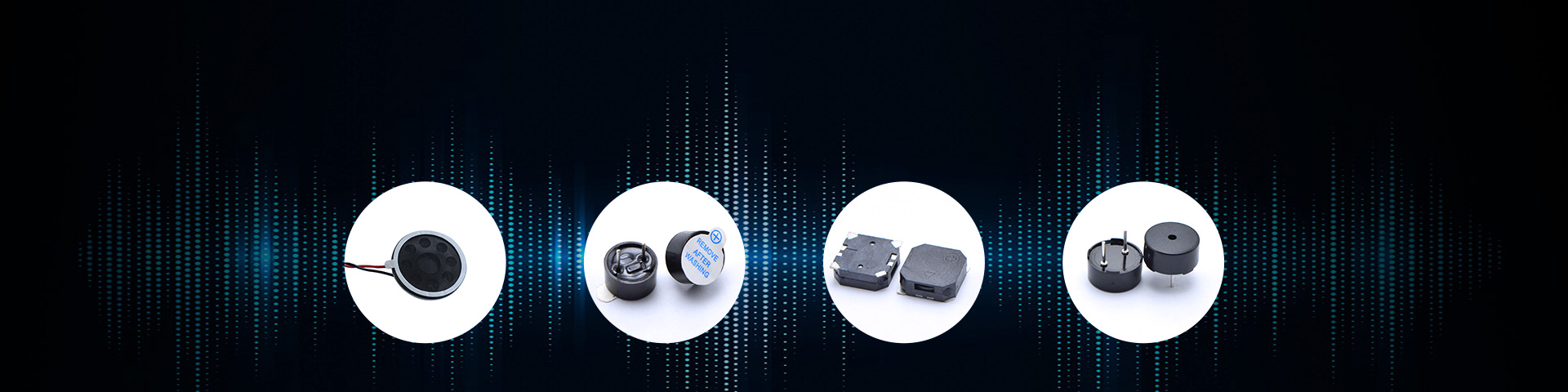

5.APPEARANCE & DIMENSIONS

|

6.Test Circuit

Measurement Circuit Vs:Source Voltage 4.5V RL:Load Resistance 2.2KΩ

|

7.Test Setup Drawing

.jpg)

8. Reliability Test

All tests should be done after 2 hours of conditioning at 20℃,R.H65% ,while the sensitivity is to be within ±3dB from the initial sensitivity after the following experiments.

8.1 High Temperature Test High temperature: +60℃ Duration: 72 hours 8.2 Low Temperature Test Low temperature: -40℃ Duration: 72 hours 8.3 Temperature Cycle Test (See in Fig.1) Low temperature: -25℃ High temperature: +60℃ Changeover time: 10min Duration: 30min Cycle: 32

8.4 Statical Humidity Test Temperature: +40℃ Relative humidity: 90~95% Duration: 72hours

|

8.5 Vibration Test Amplitude : 1.52mm Duration: 1minutes /plane Freq.range: 10~55 Hz Total time: 2 hours 8.6 Dropping Test Drop a unit unpacked onto a board of 20mm thick.

Height: 1.0 m Cycle: 6 8.7 ESD Test The microphone under test must be discharged between each ESD exposure without ground. (contact:±6KV,air:±8KV)There is no interference in operation after 10 times exposure. 9. Regarding the Soldering operation a. Use 15~ 20W soldering iron and maintain 290℃~310℃ in operation. b. Operators who work in the solder fixture and the soldering iron must be statically grounded under each soldering process. C. Soldering should be accomplished within two seconds at each terminal so as not to be overheated. d . Optimal design for heat sink pad is same as below.

|

10. List and Structure of Materials

|

NO. | Part name | Material Type | Qty | Origin | Manufacture | Remarks |

1 | PCB | FR-4 | 1 | |||

2 | FET | K596 | 1 | |||

3 | Holder | ABS | 1 | |||

4 | Back plate | Cu | 1 | |||

5 | Spacer | Mylar | 1 | |||

6 | Film | FEP | 1 | |||

7 | Outer most shell | AL | 1 | |||

8 | Cloth | Fabrics | 1 |

11. HANDLING INSTRUCTION

1、Assembly process a)、After connector and holder are once disassembled , they should not be re-used. b)、Do not touch outer springs directly(except for PCB or proper terminal set at nominal height. c)、Do not give any mechanical shocks to the micphone(e.g. dropping to floor) 2、General information 2-1: This microphone shall not be operated or stored in following environment. >where liquid(water,solvent and so on)splashes. >where the air has a high concentration of corrosive gas . >where is too dusty. >where temperature changes rapidly. 2-2: Frequency response especially in high frequency region is dependent on the structure of enclosure. Please remove additional acoustic mass or cavity in front of the microphone to the utmost. 2-3:do not put mechanical pressure more than 2 kg to the microphone. 2-4: microphone should not be in state of outgoing packing for a long-term storage. 2-5: all the soldering procedures upon microphone must be complete in a metallic device,the temperature of the soldering irons must be limited as 320℃ and less 3 s ,the operators、the solder fixtures and the soldering irons must be statically grounded under each soldering process. |

.png)

.png)

.png)

.png)

.png)

.jpg)